HENRY是各类工业组件制造商。

主营产品应用:

HENRY风扇马达

HENRY滤网和滤锅

HENRY湿度指示器

HENRY换热器

HENRY压力容器

HENRY线路组件

HENRY安全设备。

|

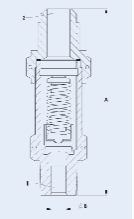

Straight-through Relief Valves - Brass

|

|

|

|

Part No

|

5232A-20.7BAR-CE

|

|

Conn Size (inch)

|

|

|

Inlet

|

1/2 MPT

|

|

Outlet

|

3/4 SAE Flare

|

|

Dimensions (mm)

|

|

|

A

|

109

|

|

ØB

|

9.5

|

|

Flow Area (mm2)

|

71.26

|

|

Kdr

|

0.67

|

|

Weight (kg)

|

0.44

|

|

CE Cat

|

Cat IV

|

HENRY泄压阀介绍

The function of a Pressure Relief Valve is to protect against over-pressure. For safety reasons, excessive over-pressure in any part of the refrigeration system must be avoided

Applications

A typical application for a Henry Technologies pressure relief valve (PRV) is to protect a liquid receiver from being over-pressurised. In the event of a fire, any liquid refrigerant inside the receiver will evaporate resulting in an increase in pressure. The PRV will safely control this increase in pressure by venting the vapour from the receiver. Another application is to protect equipment from compressor over-pressure.

Henry Technologies pressure relief valves are designed to discharge vapour and should not be used to vent liquid refrigerant. The valves are “back-pressure dependent” and are therefore required to discharge to atmosphere.

The brass and stainless steel series valves are suitable for use with HCFC and HFC refrigerant gases. The stainless steel series valves are also suitable for ammonia.

Once a PRV has discharged, replacement is recommended, as the set pressure can no longer be guaranteed. Refer to Installation Section for further information.

In line with the Institute of Refrigeration Guidelines (UK), Henry Technologies recommend that a PRV should be replaced at least every 5 years. These intervals may have to be reduced if other regulations apply.

It is recommended to have a relief valve pressure setting at least 25% higher than the maximum system operating pressure. The PRV set pressure should not be higher than the design pressure (MWP) of the vessel.

泄压阀的功能是防止过压。 出于安全原因,必须避免制冷系统任何部分的压力过高

应用领域

Henry Technologies 泄压阀 (PRV) 的典型应用是保护液体接收器免遭过压。 如果发生火灾,接收器内的任何液体制冷剂都会蒸发,导致压力增加。 PRV 将通过从接收器排出蒸汽来安全地控制压力的增加。 另一个应用是保护设备免受压缩机过压的影响。

Henry Technologies 泄压阀设计用于排放蒸汽,不得用于排放液体制冷剂。 这些阀门是“背压相关的”,因此需要排放到大气中。

黄铜和不锈钢系列阀门适用于 HCFC 和 HFC 制冷剂气体。不锈钢系列阀门也适用于氨。

一旦减压阀泄压,建议更换,因为无法再设定压力。请参阅安装部分了解更多信息。

根据英国制冷协会指南,Henry Technologies 建议至少每5年更换一次PRV。 如果其他规定适用,这些间隔可能必须缩短。

建议安全阀压力设置至少比最大系统工作压力高 25%。PRV设定压力不应高于容器的设计压力(MWP)。

HENRY泄压阀523系列其他常用型号:

HENRY 5230A-20.7BAR-CE

HENRY 5231A-20.7BAR-CE

HENRY 5231B-20.7BAR-CE

HENRY 5232A-20.7BAR-CE

HENRY 5240-20.7BAR-CE

HENRY 5242-20.7BAR-CE

HENRY 5244-20.7BAR-CE

HENRY 5246-20.7BAR-CE